Organizations must optimize processes and improve operational efficiency for sustainable growth in today's competitive landscape. Value stream mapping (VSM) is a proven technique that provides a holistic view of value flow, eliminating waste and improving efficiency. By mapping the value stream, organizations gain insights for informed decisions and continuous improvement.

VSM is crucial in industries like manufacturing, supply chain management, and services, driving productivity, cost reduction, and customer value. Businesses optimize workflows and improve the customer experience by visualizing processes and identifying improvement areas.

VSM goes beyond documentation, guiding data-driven decisions and operational excellence. In an ERP project, VSM is a powerful tool that can be utilized, providing a comprehensive view for identifying improvement opportunities, aligning with ERP goals, and ensuring a successful implementation.

What is Value Stream Mapping?

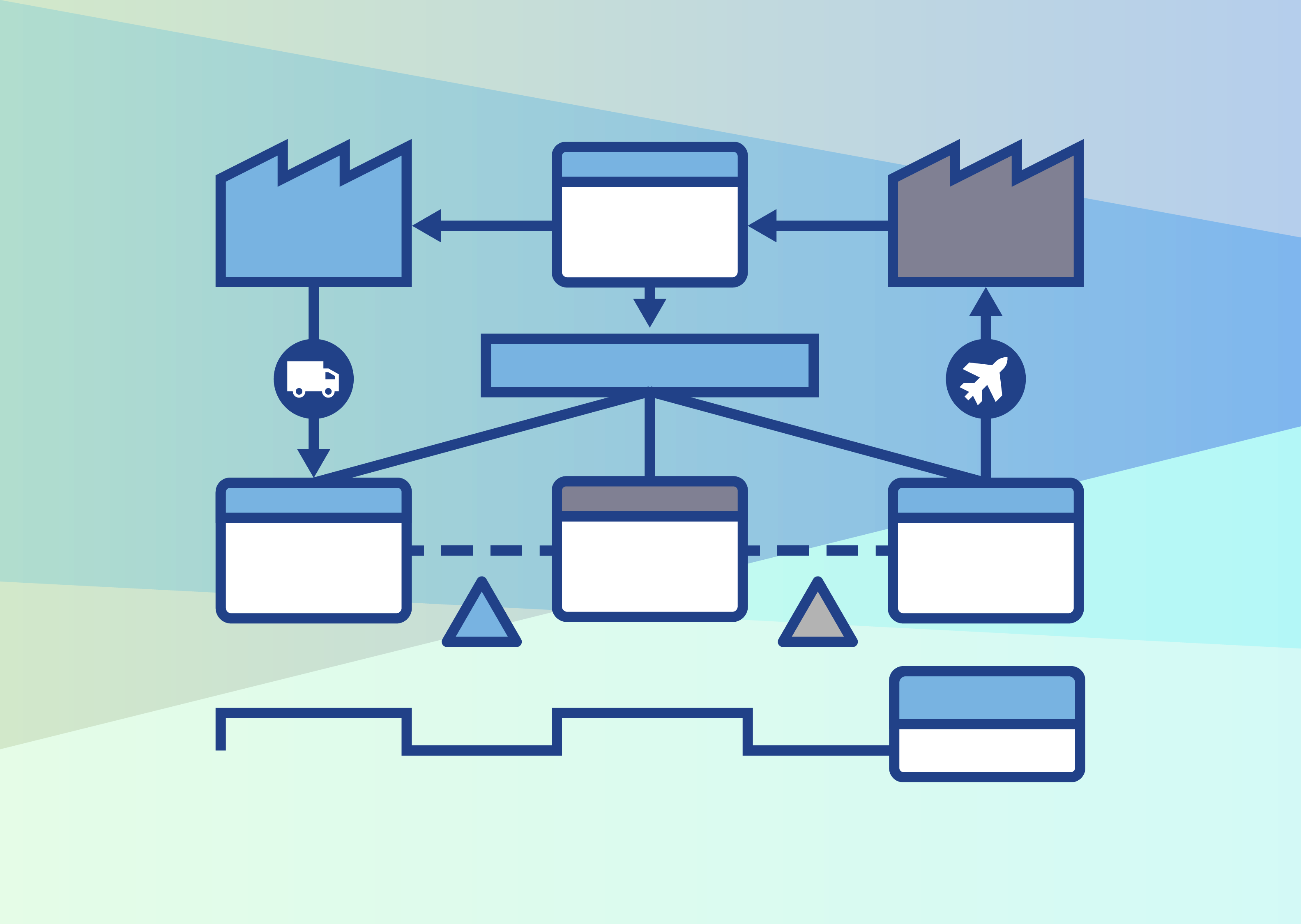

Value stream mapping analyzes and improves processes by visually mapping value flow. Toyota pioneered the tool known as a material and information flow diagram, which is an important component of the Toyota Production System. A VSM includes material/service and information flows as well as what’s considered a ‘lead-time ladder’ - or simply, the time it takes for the material/service to get to the customer. Its goal is to eliminate activities that offer no value to the customer, optimizing efficiency. VSM identifies waste within processes, such as unnecessary movement or transportation, waiting time, overproduction, overprocessing, inventory, and rework. Mapping helps eliminate or minimize these wasteful activities, improving business productivity.

A value stream map provides insights into the overall process, covering all necessary steps to address the customer’s requirements. It shows interdependencies and interactions between stages. VSM looks beyond the order of steps and takes into account cycle time, lead time, inventory, and resource utilization. This allows organizations to make decisions based on data and pinpoint areas for improvement.

How Does VSM Add Value?

Value stream mapping provides significant value to an organization's overall operational efficiency in multiple ways.

- Easy Assessment of Waste: VSM enables businesses to identify and understand waste (non value add activities) within their processes. Organizations can pinpoint areas of waste or bottlenecks enabling actions towards improving the process.

- Initiating Countermeasures in a Visual Manner: VSM provides a visual framework for identifying and implementing countermeasures. By visualizing both the current state and the desired future state of the value stream, organizations can enhance communication, collaboration, and problem-solving among team members. This visual approach makes it easier to implement changes and monitor their impact. It provides a shared understanding of the process and facilitates discussions about improvement opportunities. With a clear visual representation of the value stream, teams can effectively identify areas for improvement, create action plans, and track progress toward achieving the desired future state.

- Team Alignment for Improvement Actions: VSMs enable cross functional team alignment for improvement actions. Removing the division between shop floor and top floor disconnected decisions, VSMs enable data-centric decisions, aligning the organization.

- Simplicity and Flexibility for Process Improvement: VSM stands out for its simplicity and flexibility as a tool for process improvement. It can be adapted to many industries and company environments, allowing businesses of all sizes to benefit from its insights.

Benefits During an ERP Project

VSM is a powerful tool for ERP implementations. During an ERP project, VSM brings a multitude of benefits that significantly contribute to an implementation’s success.

- Informed ERP System Selection: VSM plays an important role in the selection of an ERP system. Organizations gain valuable insights into their existing operations by mapping out the current business processes. This understanding aids in identifying specific business process requirements. The insights guide the selection of an ERP system that aligns with the company's requirements and facilitates the desired outcomes.

- Executive Buy-In and Support: VSM is vital in gaining executive buy-in and support for the ERP project. The visual representation of processes and the identification of improvement opportunities provide compelling evidence for change. Executives can easily grasp the challenges and opportunities, leading to a better understanding of the project's importance. This, in turn, helps secure the necessary resources, support, and commitment from executives, ensuring the project's success.

- Enhanced Understanding and Optimization: VSM provides a comprehensive understanding of the current processes and key requirements that the ERP should support. By visualizing the end-to-end flow of value, it uncovers inefficiencies, bottlenecks, areas for improvement, and ERP requirements.

- Minimized Customer Disruptions: When process mapping via VSM, the activity should always start and end with the customer. This perspective aids with minimizing disruptions to customers throughout an ERP implementation.

- Improved Communication and Collaboration: VSM also serves as a powerful communication and collaboration tool. It visually represents the processes, making it easier for stakeholders to understand. By using the value stream map as a common reference point, stakeholders from different departments (or even external consultants) can collaborate more effectively, exchange ideas, and work together toward process optimization and a successful ERP implementation.

By embracing VSM, organizations gain the power to optimize their ERP, enhance operational efficiency, and achieve successful project outcomes.

Challenges and Best Practices

While value stream mapping offers significant advantages, it's important to recognize and address potential challenges and follow best practices to ensure a successful implementation.

Challenges

- Time Investment: Developing a thorough value stream map is a time commitment, which can vary based on process complexity and map scope. Companies should allow ample time and resources for data collection, stakeholder involvement, and productive mapping sessions to ensure accuracy.\

- Project Team Composition: To ensure a successful value stream mapping exercise, involving the right project team members is essential. This means involving individuals who possess extensive knowledge of the processes being mapped and can contribute valuable insights. But, it's also important to include team members who bring fresh perspectives and can challenge established practices. Striking a healthy balance between subject matter experts and those with a fresh outlook is vital for generating comprehensive and insightful maps.

Best Practices

- Pick a Pilot Part: In order to narrow the scope for an ERP Implementation, pick a part or a part family that best represents the organization.

- Walk the Process: Before mapping, walk the process to see what’s actually happening. If you are already very familiar with the process, walk it backwards, starting with the closest process to the customer.

- Involve a Cross Functional Team: Think about all the different departments the value stream crosses. Ensure subject matter experts are involved for the entirety of the exercise. Walk the process together, map the process together, and optimize the process together. ERPs are highly integrated systems so this team will need to learn how they are all going to be connected.

- Leverage an ERP Consultant's Guidance: Engaging an ERP consultant's expertise can greatly enhance the value stream mapping process. These consultants bring a wealth of experience in process improvement and can offer valuable insights and guidance at every stage of the mapping journey. Their fresh and objective perspective can help align the mapping efforts with the organization's ERP project goals and overall strategic objectives. Their expertise in ERP systems enables them to identify opportunities for optimization and ensure that the value stream map aligns with the desired outcomes of the ERP implementation.

VSM serves as a powerful tool for organizations to optimize their processes and achieve their strategic goals.

Does Your Company Need a Value Stream Map? Systems X Can Help!

After understanding the concept, benefits, challenges, and best practices of VSM, it's time to consider whether your company could benefit from implementing this powerful tool. Consider the following questions:

- Are there bottlenecks or inefficiencies in your processes that hinder operational efficiency?

- Are you embarking on an ERP implementation and want to leverage VSM?

- Are you seeking a visual and collaborative approach to drive process optimization?

- Would you like to leverage the expertise of VSM and ERP optimization professionals?

If you answered "yes" to any of these questions, Systems X is here to help. As a trusted provider of ERP solutions and process optimization services, Systems X brings extensive experience in implementing value stream mapping techniques that align with your specific business needs.

Are you ready to take your ERP processes to the next level? Don't miss out on the opportunity to optimize your business operations with VSM. Connect with Systems X today to explore the benefits of this powerful methodology for your organization. Our dedicated team is equipped with the knowledge, expertise, and support necessary to guide you through the process and help you achieve tangible results. Don't hesitate to reach out and start your journey toward process excellence and operational efficiency. Contact Systems X now and unlock the full potential of value stream mapping for your organization. Together, let's optimize your processes and achieve operational excellence.

Rebecca Bridges

:

Jul 9, 2023 8:15:00 PM

Rebecca Bridges

:

Jul 9, 2023 8:15:00 PM